There is power in precision. In fact, we believe that big things often come in the smallest of packages.

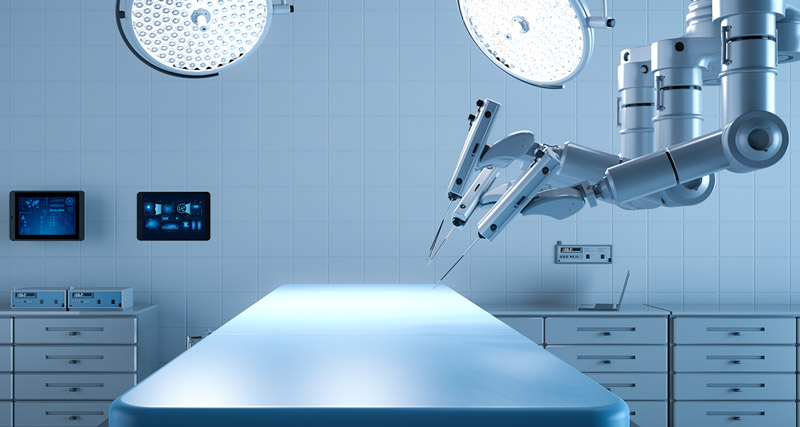

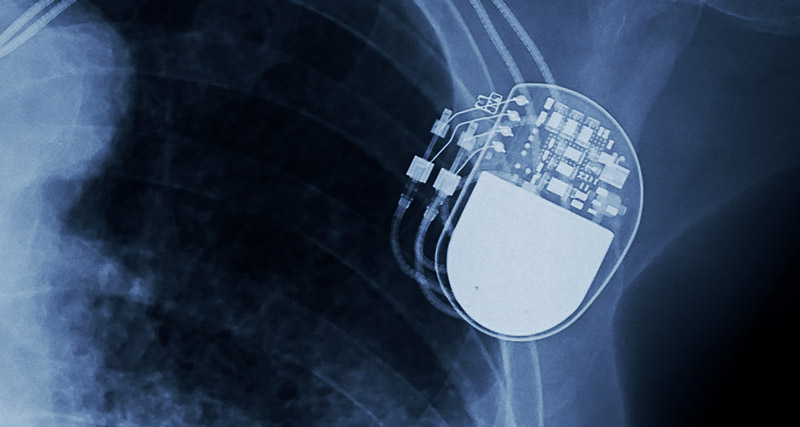

Technology products of all kinds continue to get smaller and more portable. And yet, the information that gets transmitted on them continues to grow at staggering rates. From cell phones to surgical robots and biomechanical implants to biometric machines, we make the products that power some of the most innovative new technological advancements.

Have you ever wondered how those intricate and minute connections found in medical devices are bonded?

Or thought bonding could be robust enough to withstand extreme conditions like heat and shock? Or considered what it takes for devices like these to be compatible with the human body:

The answer is simple: Pure gold.

Gold wire bonding has been the main method in the interconnection of elements – between different semiconductor devices or integrated circuits within a package. This is often the most efficient and effective way of connecting components.

As electronic components continue to get smaller, electronic connections are getting denser and tighter. This requires bonding wire that is smaller in diameter and attaches at reduced distance from its nearest neighbor. This even finer pitch, and even ultra-fine pitch, presents challenges for producing wire, bond pads, and the equipment that attaches wires to pads.

COINING manufactures gold wire in diameters as fine as 12.5 microns (0.0005 inches), with uniform length, tensile strength, and dimensions. Our fine wires can be as small as 12.5 microns and as large as 500 microns depending on the applications, specific requirements, and properties.

Gold as a Bonding Material

Gold is also a favorite material of choice for designers of high-performance electronic circuits, because of its intrinsic metallurgical properties, which include low contact resistance, ductility, and resistance to surface oxidation. Unlike many other metals, gold can be drawn micro-thin and still maintain its properties.

Gold has high electrical conductivity and strong corrosion resistance - making it an excellent material for bonding. How does it bond? Using a process called thermocompression. This process uses heat and pressure without ultrasonics during the bonding cycle.

Applications of Fine Pitch Gold Wire

Gold bonding wires can be used to meet various manufacturing requirements of the most advanced medical electronic devices - including biomechanical implants to surgical robots, portal diagnostic devices, and remote consultations.

In highly advanced medical applications like these, bonding with fine gold wire results in low signal distortion, microwave signal speeds, precision, and chemically stable products.

With 5G and the increase in RF microwave applications in the healthcare industry, attention to detail in the component packaging is becoming increasingly important. The higher the frequency at which the packages are used, the more important the wire and die connection becomes.

MORE INSIGHT ARTICLES

ADVANCED MARKET APPLICATIONS IN THE HEALTHCARE INDUSTRY

Advances in medical devices are growing exponentially, while technology is getting smaller and more reliable than ever before.

READ MORE

A GUIDE TO RECOGNIZING THE PERFECT ALLOY

Alloys make up a large part of what goes into electronic components. Understanding what to mix and how to mix makes the difference.

READ MORE

BIO-IMPLANTABLE COMPOSITE MATERIALS

Looking for improvements in battery life, reliability, and biocompatibility? Take a look at BCM’s, a cost-effective metal composite for implants.

READ MORE