Sometimes you just need to mix things up. And in the world of high-precision, high-performance components, mixing things up (metals that is) is what we’d call “standard operating procedure.”

Cliches aside, metals and alloys that make the world go round. In fact, these materials make up a large part of the structures that keep us sheltered, the vehicles that get us around, and the tools that allow us to do our jobs. Even our favorite set of golf clubs has some form of metal.

For us, metals serve alongside glass and ceramics as foundational raw elements of our trade. For this reason, we'd like to take the time to shed a little light on some of these metals and alloys. In this article, we’ll examine what makes them so valuable to us and the applications for which they will be best suited.

While you may have some idea of what you're looking for, it never hurts to refresh your memory on the options that are available. As we say, the more, the merrier. More options equal more solutions, that can address even the most unique problems.

A Match Made in Heaven... Or A Lab

Aristotle once said, “the whole is greater than the sum of its parts.” And while he likely wasn’t talking about alloys specifically, he very well could have been. Sometimes, two (or more) are better than one. And that's certainly the case in this case.

Simply put, to make an alloy, a metal is combined with one or more other metals or non-metals, often to enhance its properties. For example, steel (a mix of carbon and iron) is stronger than iron, its primary element. And while, physical properties of an alloy - things like density, reactivity, conductivity - may not differ greatly from those of its individual elements, the engineering properties - tensile and shear strength - may be substantially different. And that’s where all the magic happens.

Unlike pure metals, most alloys do not have a single melting point. Instead, they have a melting range in which the combined “substance” is a mixture of solid and liquid. But for most alloys, there is one particular proportion of constituents, known as the “eutectic mixture,” at which the alloy has a unique melting point. What is an eutectic mixture? Well, that’s a fancy way of describing a specific combination of at least two solid components that produces a change of phase to liquid at a certain temperature. Think of it as a chemical reaction of sorts - where the melting point of pure components on their own are often higher than that of the eutectic mixture.

Why does this matter? Because understanding what to mix, how to mix, and what reaction to expect makes the difference between an alloy that’s capable of making magic - or not.

What Makes The Magic Happen

When making the perfect metal alloy - it’s important to consider how it will be used, and in what context. When combining materials, our metallurgists look at a few things:

Electrical and Thermal Conductivity:

COINING understands the importance of electrical and thermal conductivity in a package and strives to maximize both. We look to design alloys that meet these crucial requirements. And we all know what heat can do to metals if you don’t have the right metals in the mix.

Corrosion Resistance:

Several factors can corrode a metal such as heat and humidity. Corrosion occurs when most or all the atoms on the surface of the metal are oxidized. Most metals are easily oxidized: they tend to lose electrons to oxygen (and other substances) in the air or in water. In some cases, alloys have a higher resistance to corrosion than pure metals. When alloying a metal, attention is paid toward specific ingredients to increase corrosion resistance.

Material Compatibility:

Some metals are pure, others are mixes. And while we love all metals and non-metals alike, they don’t always play nice in the sandbox. Finding the right partner means looking at backgrounds, characteristics, values, and traits. We like to think of it as metal-matchmaking.

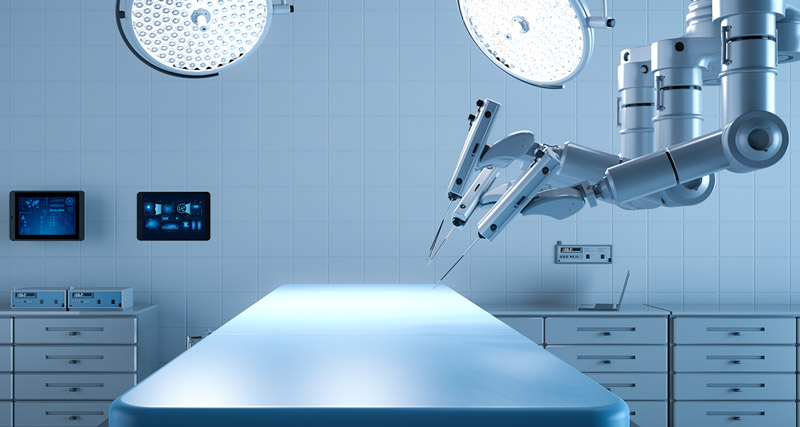

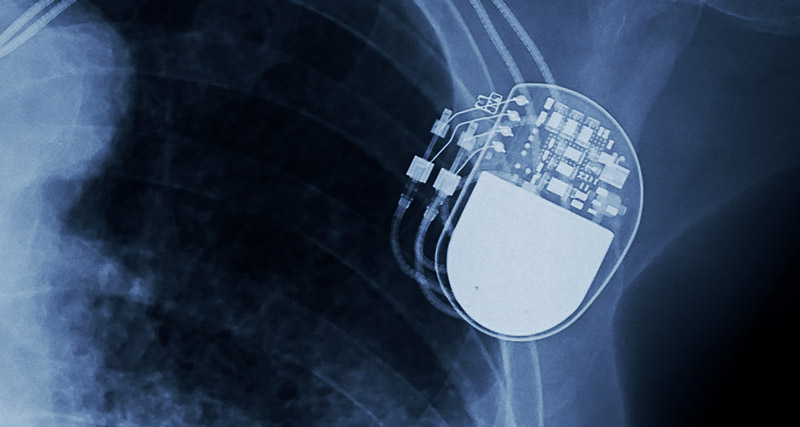

Body Compatibility (especially in the case of biomechanical implants):

High performance electronic devices drive the Healthtech industry, with biomechanical implants playing an increasingly bigger role in keeping people healthy, happy, and living life to the fullest.

Wear Resistance:

Wear is one of the big reasons high precision, high performance components fail. It goes together with corrosion. COINING has the technical expertise to recognize the failure mechanism, and we are capable to design accordingly.

COINING - A Trusted Partner

Our industry-leading laboratory is staffed with experienced chemists and metallurgists. With over 100 years of combined metallurgy and technical experience. At COINING, our chemists and metallurgists assist in the development of custom alloys that go into making micro precision-made components needed to power some of the most sophisticated technology in the world.

Our lab is equipped with the latest generation of instruments to measure alloy compositions, trace impurities, qualitative surface chemistry, and bulk physical characteristics. This means in-house we can test and verify our own custom alloys, easily work with different materials, and bring out the best, when only the best will do. Plus, we can do all this a whole lot faster than anyone else.

MORE INSIGHT ARTICLES

ADVANCED MARKET APPLICATIONS IN THE HEALTHCARE INDUSTRY

Advances in medical devices are growing exponentially, while technology is getting smaller and more reliable than ever before.

READ MORE

THE ROLE OF FINE PITCH GOLD WIRE IN IMPLANTABLE DEVICES

Ever wonder what it takes for implantable devices to be compatible with the human body? Pure gold is still the material of choice.

READ MORE

BIO-IMPLANTABLE COMPOSITE MATERIALS

Looking for improvements in battery life, reliability, and biocompatibility? Take a look at BCM’s, a cost-effective metal composite for implants.

READ MORE